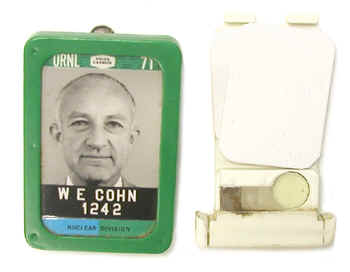

Oak Ridge National Laboratory Film Badge (ca. 1960s)

For most of the 1950s, the dosimeter used at Oak Ridge National Laboratory (ORNL) relied exclusively on NTA film for measuring neutron exposures. This meant that its useful range was limited to doses below ten rads or so. In early 1958, ORNL introduced a new badge that was capable of estimating moderate to high neutron doses. This new badge was only used for a couple of years and then it was replaced by the version of the badge shown here, the Model II.

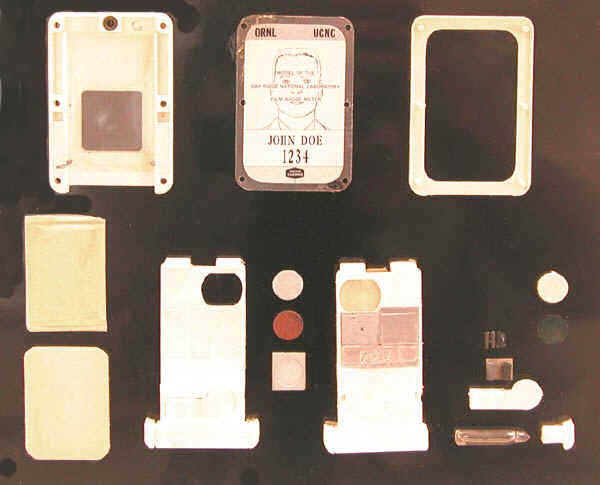

The Model II erved as the standard ORNL badge throughout the 1960s and into the 1970s. It employed two film packets: Eastman Type A film for neutrons (ca. 0.02-10 rads), and a DuPont 553 packet for beta-gamma measurements (ca. 0.03-500 rads). To evaluate high range neutron exposures, the badge incorporated a sulfur-32 pellet, an indium foil (perforated with the employee ID number), and a gold foil. To provide a capability for evaluating gamma exposures beyond the range of the film, the model II included provisions for a silver phosphate glass dosimeter and a chemical dosimeter (a channel drilled into the bottom of the badge insert).

The filters used to evaluate the beta exposures and the effective energies of the gamma/X-ray exposures were fairly complex. There were two filters on the back of the badge: a 0.062” plastic filter, and a combination filter consisting of 0.052” of plastic and 0.01” of lead. The front of the badge had four filters. One was simply a “window” of 0.02” plastic. The second was a 0.082” plastic filter. The third was a combination filter consisting of 0.02” of plastic, 0.04” of aluminum and 0.012” of plastic. The fourth, also a combination filter, consisted of (in order) 0.02” of plastic, 0.015” of cadmium, 0.005” of gold, 0.015” of cadmium and 0.012” of plastic.

The following photograph shows a display that was used to indicate the various components of the badge.

To prevent unauthorized opening of the badge, the sliding insert was locked in place with “tamperproof” magnetically operated latches. Nevertheless, a troublemaker could open the badge by inserting the end of a paperclip into the tiny hole on each side of the badge.

Size: 2 1/2” x 1 3/4” x 5/16”

Weight: ca. 33 grams

Material: Butyrate plastic

Reference

Gupton, E.D., Davis , D.M. and Hart, J.C. Criticality Accident Application of the Oak Ridge National Laboratory Badge Dosimeter. Health Physics Vol. 5:57-62; 1961.