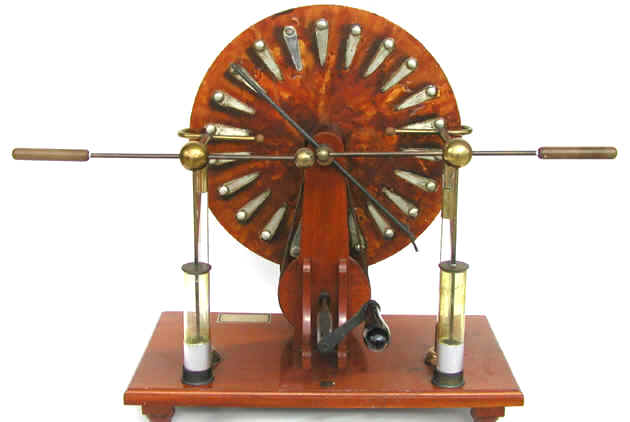

Wimshurst Static Machine (ca. 1890-1920)

This example of a Wimshurst machine was manufactured by Baird and Tatlock of London, probably sometime between 1890 and 1920.

During the decade following the discovery of X-rays, the high voltage for X-ray tubes was provided either by a static machine or by an induction coil. Static machines were relatively inexpensive and simple to set up, but they eventually fell out of favor for several reasons: they could not deliver as high a current as induction coils, they were prone to mechanical failure, and their output was often erratic. The erratic behavior was often due to high humidity. As a result, static machines were more popular in drier climates. Ironic, because our example was manufactured in London.

The unit pictured here has two glass disks which rotate in opposite directions—the disks have been coated with shellac to reduce the adsorption of water. There are twenty-two metal "sectors" on the outside edge of each disk. The sectors accumulate a charge when they come in contact with the wire "neutralizing brushes." Every time a sector comes in contact with a brush, its charge changes from positive to negative or vice-versa. The result is that the sectors have a positive charge on one half the disk and a negative charge on the other half. Some of this charge is then removed by the two U-shaped charge collectors. The charge is picked up by the pointed teeth of the collectors and transferred to one of the two glass Leyden jars (capacitors). A Leyden jar is simply a glass jar the bottom of which is lined on the inside and outside with tin foil. The device’s output voltage is estimated by the length of the spark across the spark gap formed by the two metal balls. The smaller of the two balls is connected to the positive terminal.

Later versions, designed specifically for the production of X-rays, were much larger. Some, employing more than a dozen disks up to six feet in diameter, were housed inside ornate wooden and glass cases. Devices this size had to be operated by an electric motor unlike our small unit which could be operated by hand. Encasing the disks protected them from dust, something that contributed to their unpredictability. And to help minimize the problems caused by excessive humidity, a container of calcium chloride or even a kerosene lamp might have been placed inside the cabinet.

Size: 20" x 11" base, 15.5" diameter disks

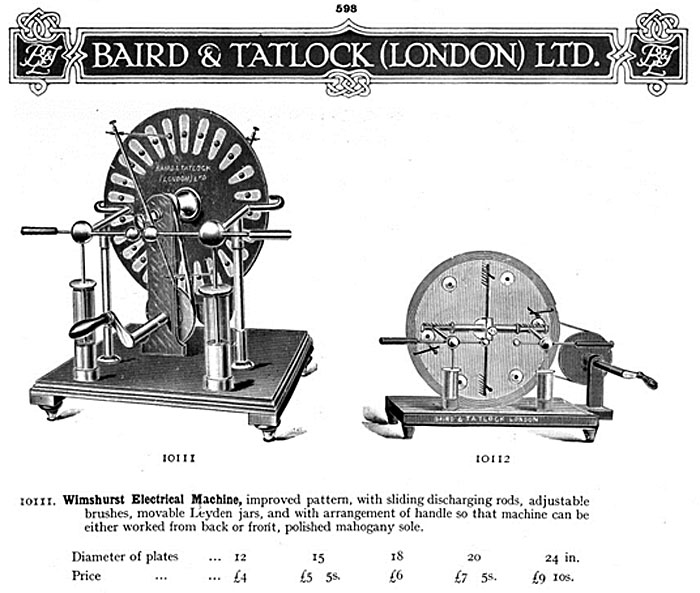

The following description of an almost identical unit is from a Baird & Tatlock catalog published in 1912.

Baird & Tatlock (London) Limited. Physical Apparatus. 1912.