Fuel Enrichment Capsule from ORNL Molten Salt Reactor

The fuel of the Molten Salt Reactor at Oak Ridge National Laboratory (ORNL) consisted of enriched uranium tetrafluoride that was mixed in a molten form with lithium and beryllium salts. The latter served as the coolant. The beauty of the molten salt fuel was that it could function at a high temperature and low pressure in liquid form. Since the fuel was a liquid, it could be cleansed of fission product impurities without the need to shut down the reactor. Perhaps the major drawback of the technology was the highly corrosive nature of the salts.

The photos show a fuel enrichment capsule from the Molten Salt Reactor that was encased in plastic and given to Dr. Alvin Weinberg. The capsule appears to be 6 1/2" long and 3/4" in diameter—it is hard to tell exactly because it is inside curved plastic.

To add fuel to the reactor during operation, the capsules were filled with uranium and salt and dipped into the core. After it had melted, the fuel-salt mix would leave the holes in the top of the capsules (see photo above right). The first use of molten salt fuel at ORNL was in the experiments of the early 1950s aimed at developing nuclear reactors for aircraft. The Molten Salt Reactor program began in 1960 shortly after an Atomic Energy Commission study determined that molten salt held out the most promise for a liquid fuel reactor. Towards the end of the program's life in the early 1970s, the reactor was being employed to breed U-233 from thorium.

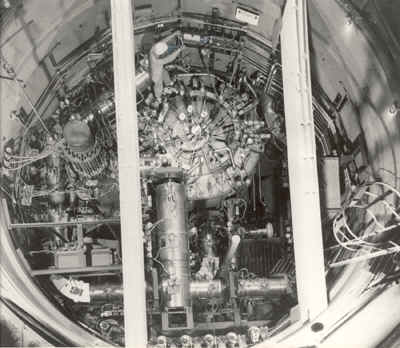

The core of the reactor (upper center in the photo to the right) was a large steel vessel. Graphite blocks, through which the fuel was pumped, served as the moderator.

Donated by Dr. Alvin Weinberg.

References

- Alvin Weinberg. personal communication.

- ORNL: The First 50 Years. Oak Ridge National Laboratory Review. Vol. 25 Nos. 3 and 4; 1992.