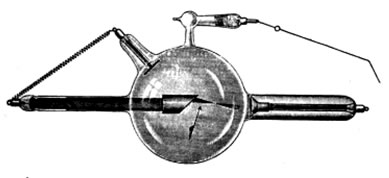

Bellevue Interrupterless Transformer Tube (1915-1925)

The Bellevue Interrupterless Transformer X-ray tube seen here was manufactured by Machlett & Son of New York city ("Machlett" is stamped on the target). As the name implies, the high voltage was to be provided by a transformer rather than an induction coil (which required an interrupter). Several patent dates, the latest being 1915, are stamped on the base of the target.

This is a bi-anode tube. In other words, it has three electrodes: a negatively charged cathode, a positively charged anode, and a positively charged anticathode.

The focused aluminum cathode is positioned in the glass arm (stem) where the latter is attached to the left side of the spherical bulb as seen in the photo. The aluminum anode is in the glass stem that attaches to the bottom right portion of the bulb—the arm that has a slight enlargement to it. I would guess that the purpose of this enlargement is to minimize the effect a static charge on the glass would have on the anode. The same thing is found in two other tubes in the collection: a Macalaster & Wiggin tube and a Kesselring tube. The anticathode is oriented in the long axis of the tube—it enters the tube inside the glass arm that is attached to the right side of the bulb.

Since the tungsten target at the free end of the anticathode (photo below right) is embedded in a relatively massive block of copper, this is what is known as a “heavy anode” tube. There was no need for a protective glass mantle around the anticathode because the tube was used with a rectified alternating currents—these mantles mitigate the problems associated with reverse currents but the latter are not a concern with rectified current.

The purpose of the sharp point projecting from the copper jacket of the target was to allow the tube to employ high currents (up to 25 amps!) without suffering internal damage or loss of efficiency.

Quoting a 1913 product notice for a "New Apparatus" from E. Machlett & Son: "A New Departure in X-ray Tubes. It has been found that the addition of a metal point, placed in the proper position on the anode of an X-ray tube, has the effect to increase the penetration of the tube in a given vacuum and produces finer detail on skiagraphic plates; furthermore, there is less heating around the cathode neck."

The glass appendage that projects from the bottom of the bulb in the photo, and from the top in the drawing, is the regulator. Its purpose was to prevent the gas pressure inside the tube from becoming too low when the tube was operating. How it worked is considered in some detail in the introduction to gas discharge X-ray tubes.

E. Machlett & Son was founded in 1897 by two glassblowers: Ernst and Robert Machlett. Although not the first (which they sometimes claimed to be), they were certainly one of the first in the United States to produce X-ray tubes for the commercial market. Headquartered in New York city, they helped introduce a number of innovative tube designs (e.g., the Piffard tube). Nevertheless, no matter how innovative they were, they could not compete with General Electric's Coolidge tube which GE patented in 1913. After 1915 or so, Machlett and Son's business dwindled, and by the late 1920s they stopped manufacturing X-ray equipment. However, GE's stranglehold on the production of hot cathode tubes was broken by the early 1930s and this allowed Robert Machlett’s son Ray to found Machlett Laboratories and re-enter the X-ray business.

So what was an interrupterless transformer?

At the turn of the twentieth century, some locations were supplied with DC current and some were supplied with AC. Increasing the voltage to that required by an X-ray tube was more straightforward with AC than DC—all a radiologist needed was a transformer. On the other hand, to step up the voltage of a direct current, an interrupter of some type was normally required. Unfortunately, there was a problem with the early AC supply systems: the frequency could vary all over the place. The solution: use a motor to produce your own reliable AC.

The interrupterless transformer was a hybrid device introduced in 1907 by Homer Snook. It used a DC (or AC) powered motor to generate an alternating current. This current was supplied to a transformer that increased the voltage. Since the stepped up current was still AC, it was then rectified. When it worked, it was impressive. It was capable of producing 100 kVp at 100 mA. The weak link was the unreliability of the valve tube that rectified the current.

Size: Approximately 21" long with 7" bulb diameter

References

- Grigg, C.R. "Trail of the Invisible Light" (p. 81)

- Product notice/ advertisement. Page 134. J. Adv. Therapeutics. March 1913.

- Ronne, P., Nielsen, A.B.W. Development of the Ion X-ray Tube. 1986.