NitroKen Tube (1919-1925)

This gorgeous tube was manufactured by the X-ray Tube Company (Rm. 1607, 100 Fifth Avenue, NYC) - the company name is stamped on the anode's copper jacket. According to a note in the March 6, 1915 issue of Electrical World (Vol 65), the company was founded "to make X-ray tubes and chemical glassware." Initially, the company president was Otto Roensch, the treasurer was M. F. Davis and the secretary was A.H. Jackson. Roensch and Davis had previously been owners of the Baker X-ray Company in NYC. By 1919, Davis and Jackson were gone and Elliot Mabee was serving as treasurer. In an interview with the Brooklyn Daily Eagle in 1934 (Oct. 16), Roensch, now at the Demuth Glass Works, indicated that he had been a glass blower since he was 10 years old in Germany. Demuth Glass Works restricted its business to fulfilling orders rather than selling directly to the public—this might also have been the business model of the X-ray Tube Company.

Etched on the glass of the vacuum regulator is the tube's brand name, "NitroKen," to which the Wappler Electric Company (173 East 87th Street, NYC) held the copyright. In its copyright claim, filed December 10, 1918, Wappler indicated that the name had been in use since November 1, 1918.

All of the references to the NitroKen tube that I have seen indicate that it was marketed by the Wappler Electric Company. My guess is that Wappler developed the tube's design and then contracted with the X-ray Tube Company to manufacture it. In 1919, Wappler was constructing a new manufacturing plant in Long Island City (The Iron Age Vol. 103 p. 1405. 1919) and they might have been unable, at the time, to manufacture the tube themselves.

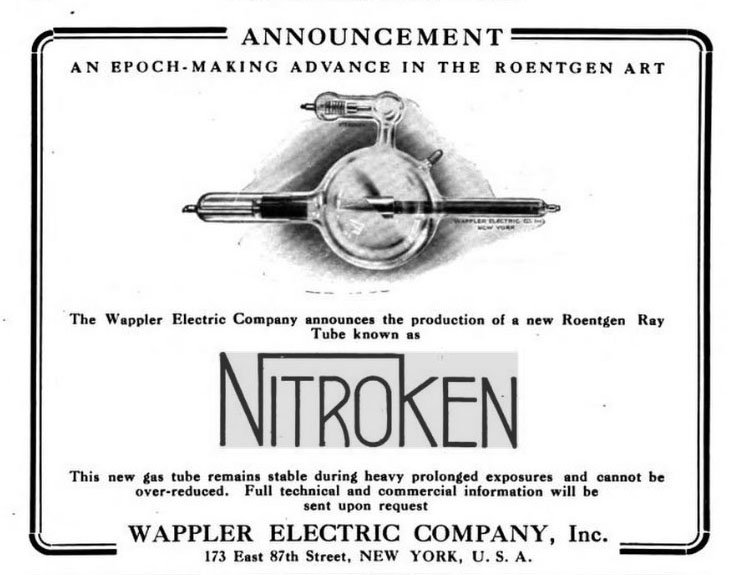

The year 1918 was a relatively late date to introduce a new type of cold cathode (gas discharge) X-ray tube—by the mid-1920s, most serious practitioners has switched to Coolidge tubes. The following ad, from 1919, modestly alerted physicians to "an epoch-making advance in the Roentgen art," i.e., the NitroKen tube. William Coolidge at General Electric probably had a different view as to the tube's importance.

The key feature of this tube is its use of nitrogen rather than air as the "residual gas," something that improved the tube's stability. Since nitrogen is less prone to interact with the tube components than oxygen, the gas pressure in the tube and its x-ray output were less likely to vary.

Needless to say, the "Nitro" in "NitroKen" alludes to nitrogen. Less obvious is the fact that the "Ken" in "NitroKen" is derived from "kronos," the Greek word meaning empty. "Ken" was also part of the name that Wappler gave to their best-known valve tube, the "Kenex." The General Electric Company deserves some credit however. In 1914 GE produced the first commercial valve tube and called it the "Kenotron." Roughly translated, Kenotron means "empty device" ("kronos" + "tron").

Considerable detail about the tube's construction and performance was provided by Dr. A. Mutscheller in "The Causes of Freakishness of Roentgen Ray Gas Tubes and Their Prevention" (Rick James would have loved that title). The paper, should you want to track it down, appeared in the March 1919 issue of the International Journal Of Surgery and it can be viewed online as a Google book. Mutscheller was an employee of Wappler Electric, so his paper is more-or-less an advertisement disguised as research, but to his credit, Mutscheller acknowledged the quality of the competition, the Coolidge tube. It seems likely that Mutscheller was the person most responsible for developing the NitroKen tube. In 1918 and 1919, he filed two key patents related to the tube, "Pressure Regulator for Vacuum Tubes" (Pat. 1,409,460) and "Safety Device for Vacuum Tubes" (Pat. 1,483,642). Mutscheller, by the way, introduced the concept of the "tolerance dose" in 1924.

Additional information can be found in Sinclair Tousey's "Medical Electricity, Rontgen Rays and Radium" starting on page 768 of the third edition (available online as a Google book). For example, Tousey points out that standard vacuum regulators could not be used with this tube because they generate water vapor, carbon dioxide or hydrogen. For this reason, the NitroKen employed a regulator containing "nitrites of thorium, aluminum and barium, which when heated liberate nitrogen." I must admit that I am disappointed that there is not enough thorium to register with a pancake GM.

One final comment. Mutscheller noted that the steel shell around the aluminum cathode (lower right side of the bulb in the top photo) protected the cathode neck from stray cathode rays (electrons) that could damage the glass. This was the "Safety Device" he referred to in his patent's title (Pat. 1,483,642).

Size: ca. 21" long and 6.5" in diameter.

Kindly donated by children of Frederick G Ouellette, Sr., with special thanks to Jeanne and Tom.