Irradiated Golf Balls

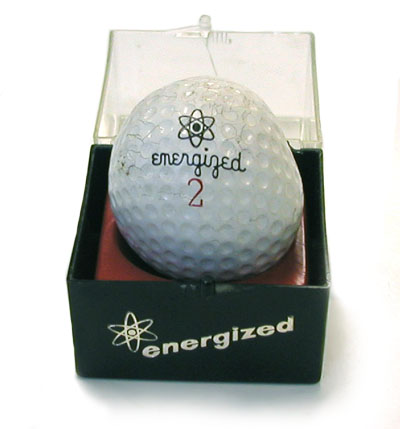

Oak Ridge Atom Industries Energized Golf Ball (1964-1968)

Yep, a mutant golf ball deformed by the ravages of radiation. To be honest, I don't know why its shape is so distorted, but it might have been because the gamma irradiation changed the tension of the winding. If the irradiation was not uniform, a distorted shape might result. Just speculating.

The ball was produced/energized in the 1960s by Oak Ridge Atom Industries, Inc. which for all practical purposes, meant Clarence J. Speas. The bottom of the box notes that the company "owns and operates its own source of radioactive Cobalt-60 under AEC Byproduct License No. 41-2540-1"

This 10 curie Co-60 source was housed in an 800-lb lead shield inside a concrete block house on Speas’ 300-acre Patchwood Research Farm.

Presumably the golf ball’s treatment with Co-60 gamma rays resulted in "longer drives... longer lives." The company also boasted that it was "the best (and most expensive) golf ball made in the USA today."

Oak Ridge Atom Industries

Oak Ridge Atom Industries possibly began operations as early as 1957 (1958 at the latest). They were incorporated in 1960.

From the Kingsport News (February 11, 1964), Oak Ridge Atom Industries

“was the first U.S. company issued a USAEC Byproduct License for the exclusive use of irradiating seed, plants and various garden products for sale to the public... Chief among its early products were Atom Blasted Seeds and Atomic Energized garden products.”

The Kingsport News article also reported that Atom Industries was also the first company in Oak Ridge, Tennessee to be traded publicly—73,750 shares of common stock valued at $295,000.

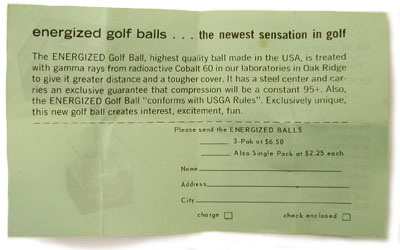

The company's first product seems to have been irradiated seeds (Valparaiso Vidette-Messenger, January 24, 1959). Other products included “Energized Potting” soil and plants (e.g., rose bushes). Nevertheless, their most widely advertised product might have been the energized golf ball featured here. One advertisement for it (Los Angeles Times, November 24, 1967) read as follows:

“Space Age Golf Balls... Why ‘Space Age’? because these exceptional golf balls are scientifically energized for greater lift, longer range. It’s an innovation by Oak Ridge Atom Industries and available in packs of 3, 6.50, packs of 12, 25.00, or singly at 2.25.”

Another ad (Chicago Tribune, December 17, 1968) claimed:

“Each ball is treated with a special gamma energizing process that guarantees over 95% compression—no other USA made ball does that. The energized steel center gives it greater distance and professional quality, the tough cover longer wear. Gives an all around livelier performance, and it putts well too.”

Sometime in 1971, the company headquarters moved to Louisville, Kentucky (Courier-Journal, June 22, 1972). The end came the following year when Food & Fibre Inc., a blueberry processing facility in Maine and the company’s sole asset, was repossessed due to a default on its mortgage. The referenced article in the Courier Journal indicated that Oak Ridge Atom Industries was “insolvent and is trying to settle with its creditors.”

As a side note, all this has a connection to Oak Ridge Associated Universities (ORAU), then known as the Oak Ridge Institute of Nuclear Studies (ORINS). Prior to starting his company, Speas had experienced trouble planting grass on a hillside on his property. He asked Dr. Marshall Brucer, the head of the ORINS Medical Division, for advice (Indianapolis Star, March 5, 1961). As I remember him, Brucer was willing to provide expert advice on pretty much any subject. In any event, Brucer suggested that exposing grass seeds to radiation might generate a new variety of grass that could survive on the hillside. This suggestion was the genesis of Oak Ridge Atom Industries. Another ORINS employee, Dr. Ralph T. Overman, seems to have served as the Technical Director for Oak Ridge Atom Industries.

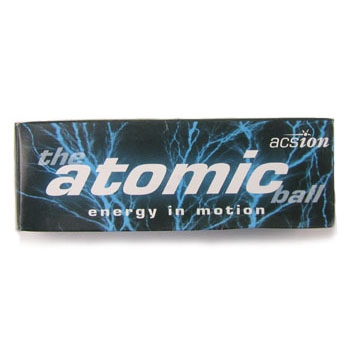

Atomic Energy of Canada Golf Ball

The ball shown below was produced by Atomic Energy of Canada Limited (AECL) in the mid 1990s. It was irradiated by an electron beam, probably the IMPELA Electron Beam Processor.

The box seen above, empty unfortunately, once held three golf balls that were irradiated in an electron beam by Acsion Industries in Pinawa, Canada. Quoting one description "The process—originally developed by AECL Research Scientists—crosslinks the atoms in the golf ball's rubber core, creating longer molecular chains. Experiments show that the Atomic Golf Ball travels up to 10% further on drives."

Apparently, these balls were handed out as souvenirs to participants at the 1995 G-7 Summit Meeting in Halifax.

Some additional information can be found in a US Patent application (0020025862) assigned to Spalding Sports:

"The golf balls of the present invention preferably are crosslinked by irradiation, and more preferably by light rays such as gamma rays or UV radiation. Furthermore, other forms of particle irradiation, including electron beam also can be used. Gamma radiation is preferred as golf balls or game balls can be irradiated in bulk. Gamma penetrates very deep but also increases crosslinking of the inner core, and the compression of the core has to be adjusted to allow for the increase in hardness. Electron beam techniques are faster but cannot be used for treating in bulk as the electron beam does not penetrate very deep. The type of irradiation to be used will depend in part upon the underlying layers. For example, certain types of irradiation may degrade windings in a wound golf ball. On the other hand, balls with a solid core would not be subject to the same concerns... Generally, a wide range of dosage levels may be used. For example, total dosages of up to about 12.5, or even 15 Mrads may be employed. Preferably, radiation delivery levels are controlled so that the game ball is not heated above about 80 degree C (176 degree F) while being crosslinked."