Radioluminescent Items

Note: We are not interested in donations of additional radioluminescent items and we do not recommend that these sorts of things be collected by the general public.

Radioluminescent Paint

Paul Frame, Oak Ridge Associated Universities

General

Radioluminescent paint consists of a radioactive material mixed together with a luminescent crystalline powder. The first radioactive material to be used was radium-226 (Ra-226), but it hasn't been employed since the 1970s, at least in the U.S. Today, tritium (H-3) and promethium-147 (Pm-147) are the radionuclides of choice. Other radionuclides have also been used, e.g., strontium-90 (Sr-90) and carbon-14 (C-14). Zinc sulfide powder has been the most widely used luminescent material.

The light emitted by the paint is due to the radiation energy deposited in the luminescent crystals by alpha and/or beta particles. Next to no light is due to gamma rays.

Some of the radiation energy deposited in the crystals promotes electrons from the valance band to the conduction band (these are different energy levels of electrons in the crystal). Electrons in the valance band are fixed in place, but they become mobile in the conduction band. Once they have been promoted to the conduction band by the radiation, the electrons move to positively charged activator sites (e.g., copper, manganese, or silver impurities). When the electrons reach an activator, it is left in an excited state. When the activator deexcites, a photon of light is emitted. The greater the number of alpha or beta particles striking the crystals, and the greater the energy deposited in them, the brighter the light.

Radium

Radium-226 is an alpha emitter with a 1600 year half-life. It emits a gamma ray at 186 keV. Radium decays into a number of short lived decay products that can usually be expected to be present at, or close to, the same activity as the radium. These decay products (Rn-222, Po-218, Pb-214, Bi-214, Po-214, Pb-210, Bi-210, and Po-210) emit alphas, betas and gamma rays.

A Little History

By itself, radium in high enough concentrations will glow blue, a phenomenon first observed by Marie and Pierre Curie. That the radiation emitted by radium would cause various materials, such as zinc sulfide, to fluoresce was first recognized by Henri Becquerel. The invention of radioluminescent paint can be attributed to William J Hammer who mixed radium with zinc sulfide (in 1902), and applied the paint to various items including watches and clock dials. In a case of bad judgment, he failed to patent the idea. Recognizing a good opportunity, a gemologist at Tiffany & Company, by the name of George Kunz, did patent it. Kunz and Charles Baskerville, a chemist, made their paint by mixing radium-barium carbonate with zinc sulfide and linseed oil.

At that time, at least in the US, radioluminescent paint saw little application. It stayed in the bottle. But in Europe, especially Switzerland, things were different. Quoting Ross Mullner "there were so many radium painters in that country that it was common to recognize them on the streets even on the darkest nights because of the glow around them: their hair sparkled almost like a halo."

In the United States, the first company to produce radioluminescent paint was the Radium Luminous Material Corporation in Newark, New Jersey. It was founded in 1914 by Sabin von Sochocky and George Willis, both physicians. Their operations expanded tremendously when the United States entered World War I, and in 1917 they moved from Newark to Orange, New Jersey. They also got into the business of mining and producing radium. In 1921, they changed their name to the U.S. Radium Corporation.

The brand name for the radioluminescent paint produced by U.S. Radium Corporation was "Undark." Standard Chemical Company used the name "Luna" and the Cold Light Manufacturing Company, a subsidiary of the Radium Company of Colorado, made "Marvelite."

According to NCRP Report No. 95, radium has not been used in radioluminescent watches since 1968, or in clocks since 1978 (these dates are approximate).

The Paint

Quoting Ed Landa: "zinc sulfide was mixed with a radium salt to yield products containing about 25 to 300 ug [one ug is essentially the same as one uCi] of radium element per gram. The more concentrated preparations (generally containing 215 ug of radium per gram to meet British Admiralty standards) were used on aircraft and ship instrument dials, while lower-grade materials containing about 50 to 100 ug of radium per gram of mixture were used on watches, switch markings, and other devices requiring less critical reading." According to a Department of Commerce Information Circular from 1930, the paint might contain "from 0.7 to 3 and even 4 milligrams of radium element to 100 grams of zinc sulfide. Impurities may be added to the zinc sulfide as follows: Cadmium, 0.05 per cent; copper, 0.001 per cent; manganese, 0.0002 per cent."

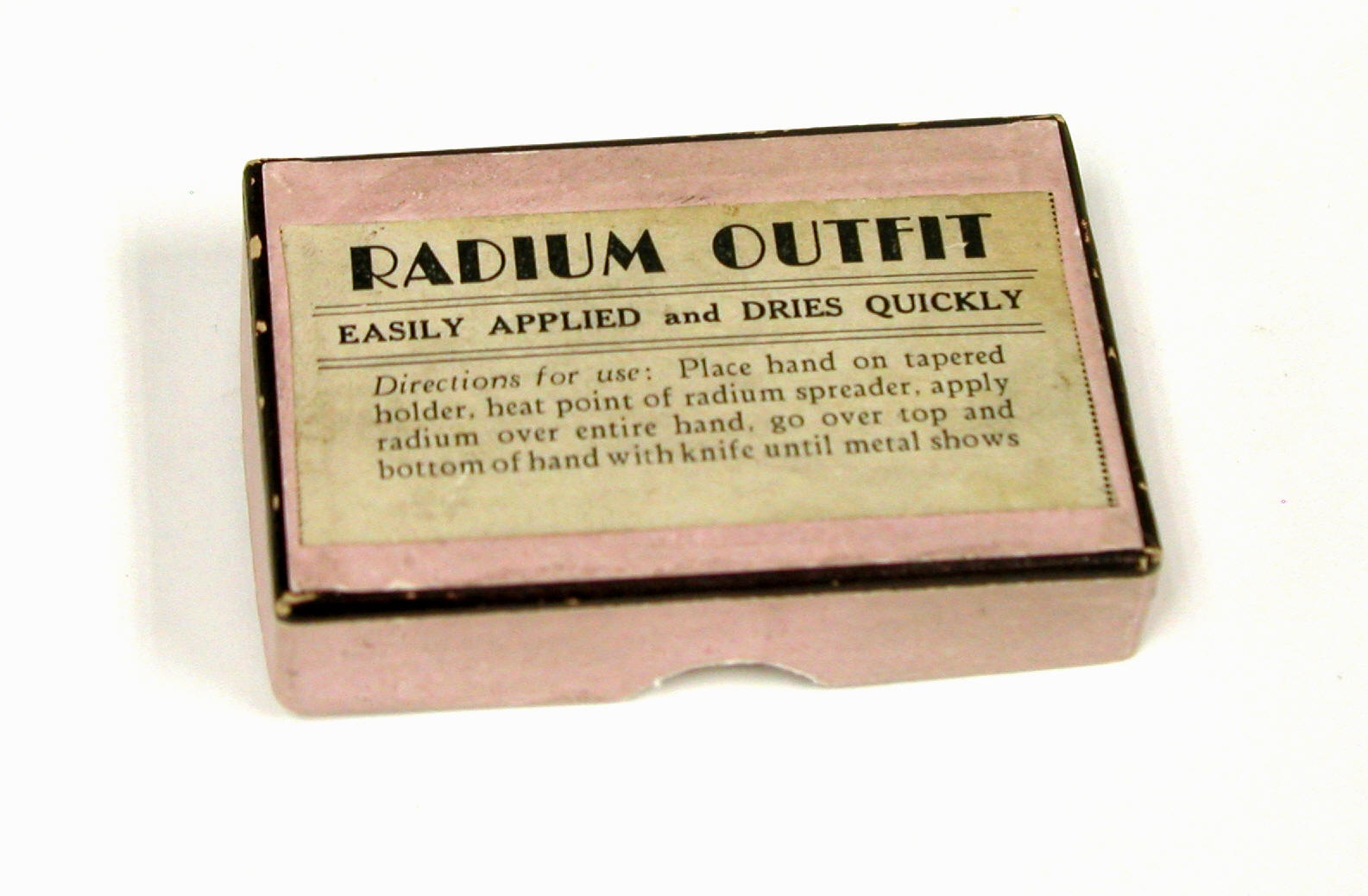

While the radium-zinc sulfide mixture could be placed directly in glass vial and used, a paint had to include some sort of adhesive, e.g., lacquer or gum binder. No more adhesive than necessary would be used because the adhesive would absorb some of the alpha particle energy before it could be deposited in the zinc sulfide.

The radium was usually in the form of radium sulfate—the latter is less soluble than the other radium salts that were available (radium bromide and radium chloride).

The Deterioration of the Paint's Luminosity

Over time, the intensity of the glow from the paint will decrease because of the damage caused to the ZnS crystals by the alpha particles. Since radium-226 has a 1600 year half life, its decay is not a significant factor. Robley Evans once told me that he could estimate how old radioluminescent paint was by examining the size of the ZnS crystals under a microscope. As I understand it, the crystals actually begin to fragment because of the damage caused by the alpha particles. The damage presumably prevents electrons in the conduction band from reaching the activator sites (e.g., copper, silver) where the light would be emitted. The higher the activity of the radium-226 (and the brighter the luminescence) the faster the deterioration. One early report by Charles Viol stated that the reduction in the luminescence was due, at least in part, to a radiation-induced discoloration of the zinc sulfide crystals. He also indicated that the damage could be reversed by heating the paint. This explanation is plausible and might provide a partial explanation for the decreased luminosity of old paint, but I have my doubts. One of the best kept trade secrets of the various manufacturers was how they minimized the inevitable decrease in the luminosity of their paint. A couple of the factors that would affect this decrease in luminosity would be the amount of the radium, and the size and concentration of the zinc sulfide crystals. I suspect that the type and concentration of the activator sites would also play a role.

In the 1920s, "mesothorium" was sometimes added to the paint. Mesothorium is the historical name given to radium-228 (5.8 year half-life). Ra-228 is a beta emitter, but over time it decays into thorium-228 (1.9 year half-life), an alpha emitter. The result is that the intensity of the light from the paint will increase over the first five years or so due to the in-growth of the Th-228. The practice of adding mesothorium ended by 1930. Any mesothorium that might have been used will no longer be present, it has long since decayed away.

Radium-226 Activity in Timepieces

The activity in timepieces varies tremendously depending on the size of the hands and the dials as well as the concentration of radium in the paint.

The following table comes from "The Use of Radium in Consumer Products," a 1968 publication of the US Public Health Service.

Publication Average Radium Activity per Watch Range of Radium Activity

- British Medical Research Council (1956) 0.2 uCi

- Glaser, Germany

- (1957) 0.035 uCi 0.03 - 0.042 uCi

- (1958) 0.045 - 0.1 uCi

- Joyet, Switzerland

- (1958) 0.36 uCi 0.06 - 0.81 uCi

- (1960) 0.144 uCi 0.106 - 4.460 uCi

- Flatby & Koren, Norway (1959) 0.19 uCi

- Seelentag & Klotz, Germany (1959) 0.04 uCi 0.008 - 0.095 uCi

- Seelentag & Schmier, Germany (1961) 0.014 uCi 0.002 - 0.885 uCi

In one study of 18 pocket watches, the National Center for Radiological Health measured radium contents of 0.6 to 1.39 uCi.

There is almost no information available about the average activity of radium in clocks, nevertheless, it is known that the average activity in the clock dials from one manufacturer during the early 1970s was 0.5 uCi.

Various Uses of Radioluminescent Paint

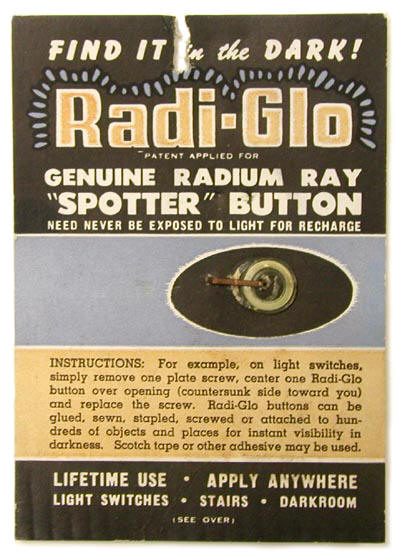

The April 1920 Issue of Scientific American noted that more than 4,000,000 watches and clocks had been produced using radium-containing radioluminescent paint. The following items were identified in the article as containing radioluminescent paint: house numbers, keyhole locators, ship's compasses, telegraph dials, mine signs, steam gages, pistol sights, poison bottle indicators, bedroom slipper buttons, furniture locator buttons, theater seat numbers, automobile steering-wheel locks, luminous fish bait, and glowing eyes for toy dolls and animals.

Estimated Doses

NCRP Report 56 indicated that the estimated average dose equivalent to the gonads of an individual wearing a radium-containing watch was approximately 3 mrem per year. The estimated dose from a watch containing 4.5 uCi of radium, a very large amount, would be 310 mrem per year to the gonads. Note that the associated risk here is much lower than if the dose had been the same over the entire body.

In the previously mentioned study of pocket watches by the National Center for Radiological Health, measurements using TLDs and a human phantom indicated that the annual dose to the gonads was 60 mrem (assuming that the watch was worn 16 hours per day).

Based on the results of one survey conducted in Tennessee, the average whole body exposure due to a radium-containing radioluminescent clock might be on the order of 7 to 9 mrem per year. Exposure rates to the head would be somewhat higher, possibly 5-10 times higher, because these are usually alarm clocks that would be positioned on a night stand near the head of the bed.

Radium Dial Painters

During the 1920s, the radium paint was applied to clock and watch components in a variety of ways: painting it on with a brush, painting it with a pen or stylus, applying it with a mechanical press, and dusting. The latter procedure involved dusting a freshly painted dial with radioluminescent powder so that the powder would stick to the paint.

The original practice of using the mouth to put a point on a brush is described as follows by Robley Evans: "In painting the numerals on a fine watch, for example, an effort to duplicate the shaded script numeral of a professional penman was made. The 2, 3, 6, and 8 were hardest to make correctly, for the fine lines which contrast with the heavy strokes in these numerals were usually too broad, even with the use of the finest, clipped brushes. To rectify these broad parts the brush was cleaned and then drawn along the line like an eraser to remove the excess paint. For wiping and tipping the brush the workers found that that either a cloth or their fingers were too harsh, but by wiping the brush clean between their lips the proper erasing point could be obtained. This led to the so-called practice of "tipping" or pointing the brush in the lips. In some plants the brush was also tipped before painting a numeral. The paint so wiped off the brush was swallowed."

It might be worth noting that tipping the brushes was not something the dial painters just decided to do. At least in some plants they were actually trained how to do it. In fact, the instructors sometimes swallowed some of the paint to show it was harmless. It has been estimated that a dial painter would ingest a few hundred to a few thousand microcuries of radium per year. While most of the ingested radium would pass through the body, some fraction of it would be absorbed and accumulate in the skeleton. Later on, Robley Evans would establish a maximum permissible body burden for radium of 0.1 uCi.

As a result of the ingestion of the radium, many of the dial painters developed medical problems of varying degrees of severity. The first deaths occurred in the mid 1920s, and by 1926 the practice of tipping the brushes seems to have ended.

Tritium

Tritium (H-3) is a low energy beta emitter with a 12.3 year half-life. It does not emit gamma rays.

For a short time during the 1970s, tritium containing gas tube light sources (GTLS) were used to backlight liquid crystal display (LCD) watches. At that time, a typical activity for GTLS was 200 mCi. The sealed tubes, made of borosilicate glass, were 0.5 to 1.0 cm long, and one or two millimeters in diameter. The inside wall of the tube was coated with the luminescent material while the tritium was present as a gas. Since then, similar but smaller tubes attached to the hands and dial faces of analog watches have been used. I don't have much information about the activities in these watches but it seems that they range from about 25 to 100 mCi.

When incorporated into radioluminescent paint, much lower activities (2 mCi) are employed. The tritium, which is really hydrogen, is incorporated into a polymer that also contains the luminescent material (usually ZnS).

The dose to wearers of tritium-containing radioluminescent watches is due to the leakage of tritium from the device and the tritium then being absorbed through the skin. The betas emitted by tritium are of too low an energy to penetrate the watch case and contribute to the dose. Measured leakage rates from watches employing tritium containing paint were up to 83 nCi (0.083 uCi) per day in one study, and 1 to 370 pCi per minute in another (0.0014 to 0.5 uCi per day). The typical release rate from watches using tritium sealed in glass tubes (e.g., GTLS) is less than 0.00025 uCi per hour. As such, the H-3 activities in GTLS might be higher than those in paint, but the resulting doses are somewhat lower.

Estimates of the doses to individuals wearing tritium-containing watches vary:

- Fitzsimmons (1972) 0.2 to 1.8 mrem per year with an average of 0.6 mrem per year

- Buckley et al (1980) 0.06 mrem

- Moghissi and Carter (1975) 0.8 urem/27 uCi. This equates to 0.06 mrem per year for a watch with 2 mCi

NUREG-1717 calculated both the dose to the skin in direct contact with the watch case, and the dose due the absorption through the skin of tritium in the general room air. The latter dose not only applies to the wearer of the watch, it also applies to anyone in the same room as the wearer of the watch. Assuming that the watch employed 2 mCi of tritium in paint, and that the watch was worn 16 hours per day, the average dose to the 10 cm2 of skin in contact with the watch was calculated to be 200 mrem. This can be converted into an effective dose equivalent (essentially a whole body dose) of 0.02 mrem per year. The effective dose equivalent due to the tritium in the general room air was essentially the same, i.e., 0.02 mrem. The total effective dose equivalent to the individual wearing the watch would therefore be 0.04 mrem per year.

Promethium-147

Promethium-147 (Pm-147) is a low energy beta emitter with a 2.6 year half-life. It emits a gamma ray at 121 keV in a small fraction of its decays.

The Pm-147, mixed together with ZnS in a polymer paint, is either an insoluble oxide or is incorporated into ceramic microspheres.

For a watch or clock containing Pm-147, the activity is approximately 0.05 mCi (50 uCi).

The dose to an individual from a Pm-147 containing timepiece is due to the emission of Bremmstrahlung and gamma rays. The low energy beta particles cannot penetrate the case.

According to NUREG-1717, a person continuously wearing a watch containing the maximum allowable level of Pm-147 would receive less than 400 mrem to a small area of skin on the wrist and less than 1 mrem to the gonads. NUREG-1717 also calculated the effective dose equivalent to the wearer of a Pm-147 containing watch using two scenarios. In one, the effective dose equivalent was estimated to be 0.2 mrem per year. In the other scenario, the estimated effective dose equivalent was 0.4 mrem per year. The estimated effective dose equivalent to a homeowner due to a clock containing Pm-147 was 0.002 mrem per year. For the purpose of these calculations, the activity was assumed to be 100 uCi per timepiece (watch or clock).

The National Radiological Protection Board (NRPB) of Great Britain estimated that the use of a Pm-147 containing pocket watch would result a dose to the gonads of up to 0.2 mrem and a maximum dose of 35 mrem to the skin.

Strontium-90

Sr-90 has not, at least to my knowledge, been used in timepieces. Nevertheless, in the early 1950s the U.S. military began to use Sr-90 instead of Ra-226 in its radioluminous personnel and deck markers. Sr-90 is a pure beta emitter (although there can be substantial bremsstrahlung production) with a 30 year half-life. The high energy betas associated with Sr-90 are actually produced by its short-lived decay product, Y-90. Sr-90 and Y-90 are almost always present together in the same activities (i.e., in secular equilibrium).

Strontium had three major advantages over radium: a greater variety of luminescent colors were possible with strontium than radium, the gradual decrease in luminous intensity was minimal because strontium's beta particles did less damage to the zinc sulfide crystals that radium's alpha particles, and the photon (bremsstrahlung) emissions from strontium were less of a safety concern than the gamma rays from radium.

Regulatory Limits

The regulations set forth by the Nuclear Regulatory Commission (NRC) in 10 CFR 30.15 state that an individual does not need a license to possess timepieces if the following specifications are not exceeded:

(i) 25 millicuries of tritium per timepiece,

(ii) 5 millicuries of tritium per hand,

(iii) 15 millicuries of tritium per dial (bezels when used shall be considered as part of the dial),

(iv) 100 microcuries of promethium 147 per watch or 200 microcuries of promethium 147 per any other timepiece,

(v) 20 microcuries of promethium 147 per watch hand or 40 microcuries of promethium 147 per other timepiece hand,

(vi) 60 microcuries of promethium 147 per watch dial or 120 microcuries of promethium 147 per other timepiece dial (bezels when used shall be considered as part of the dial),

(vii) The levels of radiation from hands and dials containing promethium 147 will not exceed, when measured through 50 milligrams per square centimeter of absorber: (A) For wrist watches, 0.1 millirad per hour at 10 centimeters from any surface, (B) For pocket watches, 0.1 millirad per hour at 1 centimeter from any surface, (C) For any other timepiece, 0.2 millirad per hour at 10 centimeters from any surface.

Note that it is possible to petition the NRC under the provisions of 10 CFR 30.19 to produce timepieces with activities exceeding those in 10 CFR 30.15.

References

- US Public Health Service. The Use of Radium in Consumer Products. MORP 68-5. 1968.

- Arthur Keane. Radio-active Luminous Paints. Scientific American Supplement. 84: 126-127; August 25, 1917.

- Ed Landa. Buried Treasure to Buried Waste. Colorado School of Mines Quarterly 82 (2); 1987.

- Ross Mullner. Deadly Glow. The Radium Dial Worker Tragedy. American Public Health Association. 1989.

- National Council on Radiation Protection and Measurements. Radiation Exposure from Consumer Products and Miscellaneous Sources. NCRP Report No. 56. 1977.

- National Council on Radiation Protection and Measurements. Radiation Exposure of the U.S. Population from Consumer Products and Miscellaneous Sources. NCRP Report No. 95. 1987.

- National Radiological Protection Board. Board Statement on Approval of Consumer Goods Containing Radioactive Substances. Vol 3 (2); 1992.

- Nuclear Regulatory Commission. Systematic Radiological Assessment of Exemptions for Source and Byproduct Materials. NUREG-1717, June 2001.

- Louis Schwartz et al. Health Aspects of Radium Dial Painting I, II, III, and IV. Journal of Industrial Hygiene Vol 15 Sept 1913: 362-382; Vol 15 November 1913: 433-455.

- Charles Viol. The Commercial Production and Uses of Radium. J. of Chemical Education 3(7): 757-772; 1926.

- U.S. Department of Commerce. Radium. Information Circular. I.C. 6312. August 1930.

-

"Radieye" Screws "Radieye" Screws

-

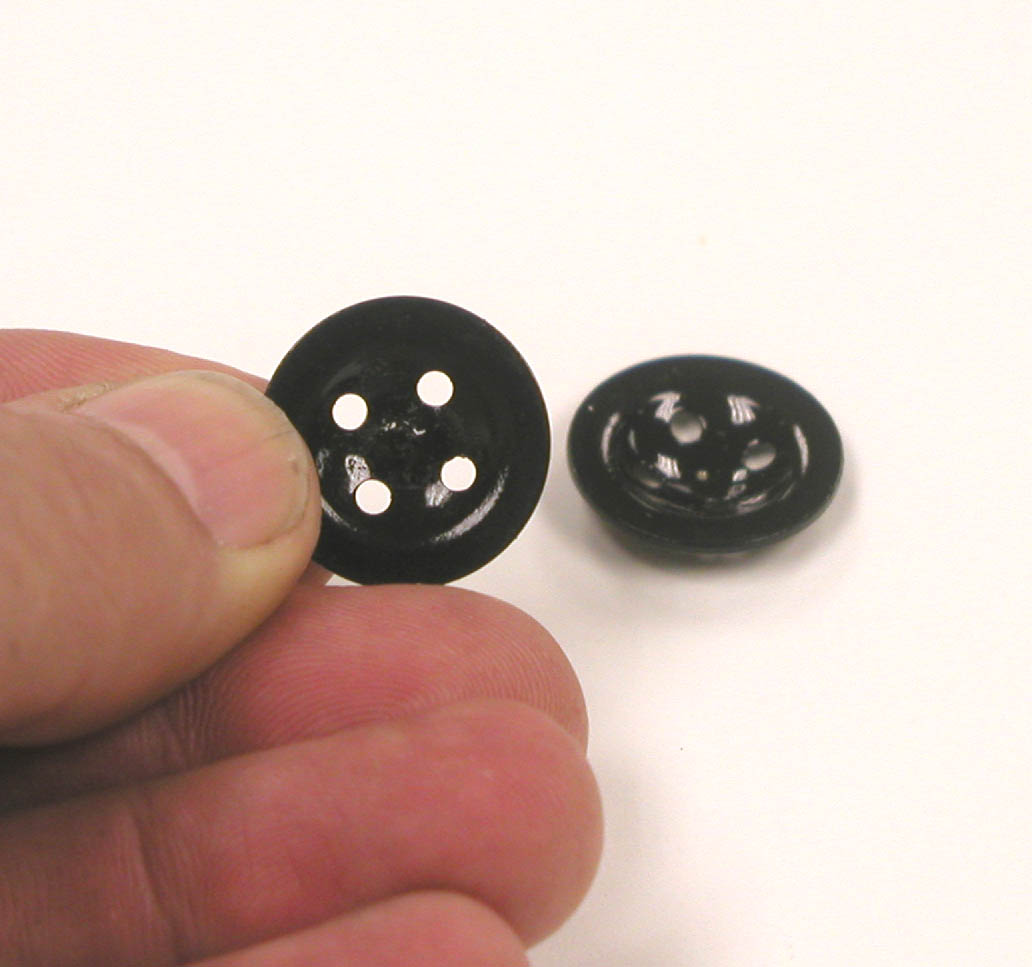

Buttons Buttons

-

Chain Pulls Chain Pulls

-

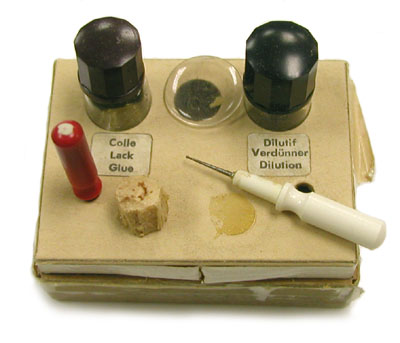

Favorite Touch-up Kit Favorite Touch-up Kit

-

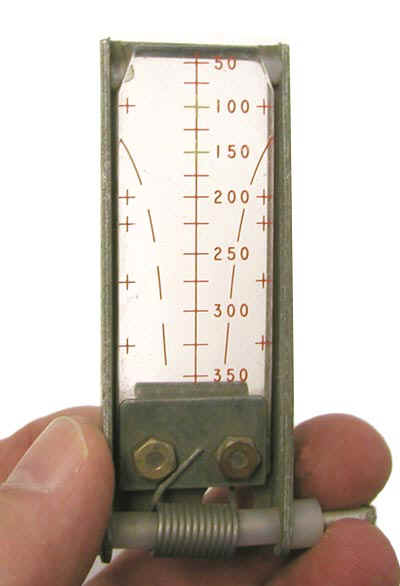

Gauge Gauge

-

Hi-Test Radium Touch-up Kit for Watches Hi-Test Radium Touch-up Kit for Watches

-

Military Compass Military Compass

-

Personnel Markers Personnel Markers

-

Radi-Glo "Spotter" Button Radi-Glo "Spotter" Button

-

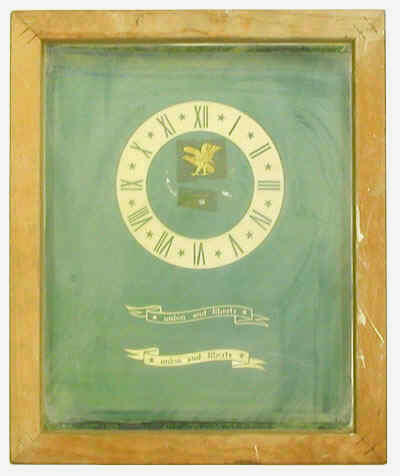

Radium Clock Face Radium Clock Face

-

Radium Dial Watch Radium Dial Watch

-

Radium Hands for Watches Radium Hands for Watches

-

Radium Outfit Touch-up Kit Box Radium Outfit Touch-up Kit Box

-

Rope Rope

-

Sight for LAW Rocket Launcher Sight for LAW Rocket Launcher

-

Silk Screen for Clock Face Silk Screen for Clock Face

-

Sun Ray Touch-up Kit for Watches Sun Ray Touch-up Kit for Watches

-

The "Glowbody" Minnow Fishing Lure The "Glowbody" Minnow Fishing Lure

-

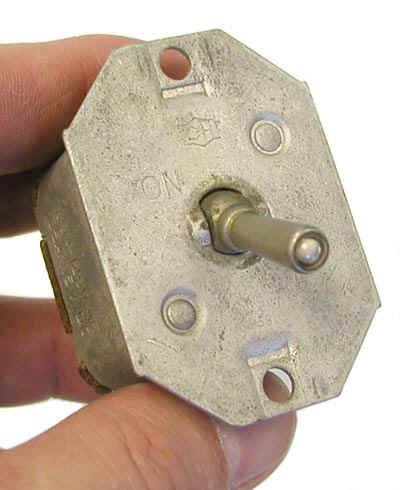

Toggle Switch Toggle Switch

-

Touch-up Kit of Unknown Manufacture Touch-up Kit of Unknown Manufacture

-

Tritium Exit Sign Tritium Exit Sign

-

Tritium Sight for M-16 Rifle Tritium Sight for M-16 Rifle

-

WWII RAF Button Compass WWII RAF Button Compass